Product lifecycle management (PLM) is a way for businesses to guide a product through all its stages, from its start as an idea to when it’s no longer in use. It helps teams work better together, cut down on costs, and get products to market faster. By focusing on each step PLM ensures that products reach their full potential while staying competitive.

Table of Contents

PLM also makes it easier to handle product data, improve quality, and adjust to changes in the market. Whether it’s creating something new or improving an existing product, this approach gives companies the tools to stay organized and focused. With advancements in technology, PLM systems are becoming even more important for businesses to succeed. This blog will cover the basics of PLM, its benefits, and how it’s shaping the future of product management.

What Does Product Lifecycle Management (PLM) Mean?

Product lifecycle management (PLM) is a strategic process that manages a product’s journey from its initial idea to its retirement. It integrates people, data, processes, and systems to optimize every stage of the product life cycle. PLM ensures seamless collaboration across teams, enabling businesses to design, develop, launch, and improve products efficiently. PLM helps reduce costs, improve product quality, and accelerate time-to-market by offering a centralized platform for managing product information. This approach is widely used in manufacturing, technology, and retail industries to enhance innovation and stay competitive in dynamic markets.

Elements of Product Lifecycle Management

1. Product Design and Development

This is the stage at which product concepts are turned into physical designs. It entails conducting market research, prototyping, and refining concepts based on client requirements and technical feasibility. By matching product features with market expectations, firms can ensure that their goods are both unique and practical, laying the groundwork for successful development and subsequent stages.

2. Data Management

Effective data management is critical for tracking all product-related information. This contains design information, specifications, regulatory documentation, and test results. By centralizing product information in a PLM system, teams can interact more efficiently, decrease errors, and make sure everyone has access to up-to-date and correct product data, resulting in better decision-making.

3. Collaboration and Communication

Collaboration tools in PLM enable teams from different departments to work effortlessly together. These tools improve communication across design, engineering, marketing, and production teams, ensuring all stakeholders are coordinated throughout the product’s lifecycle. Timely and clear communication reduces delays, speeds up product development, and enhances overall product quality.

4. Manufacturing and Production

Once a product is designed, the focus shifts to manufacturing and production. PLM ensures that manufacturing processes are optimized, with the right materials, designs, and processes in place. It helps coordinate between suppliers, production lines, and quality control to deliver products that meet specifications while reducing production costs and time.

5. Product Retirement and End-of-Life (EOL) Management

As products approach the end of their lives, PLM helps manage their retirement. This includes preparing for product discontinuation, disposal, or recycling of electronic devices. It guarantees that all associated resources, data, and inventories are appropriately managed, reducing waste and providing insights into how the product’s life can be used to guide future product development and improvement.

Also read: Building a Product Launch Plan for New Product Marketers

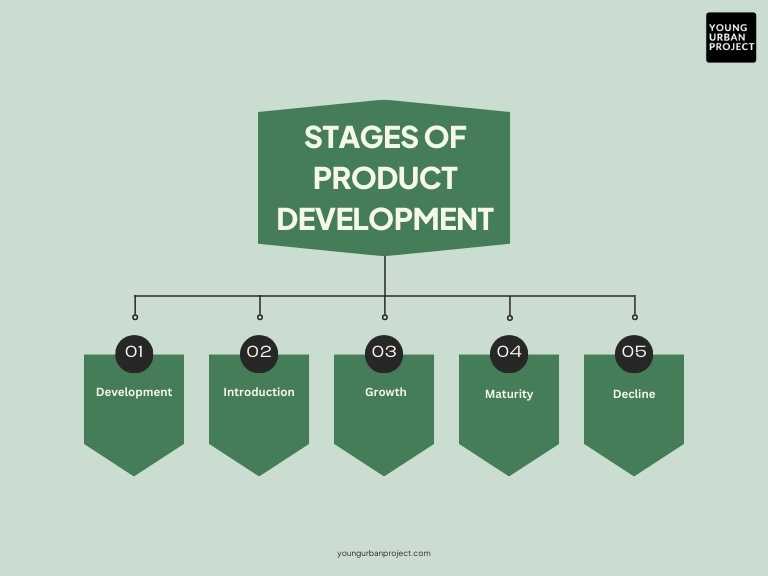

The Stages of Product Development

1. Development

The development stage is the initial step of the product life cycle, during which the product is planned and built. This stage involves carrying out research and development (R&D), designing, prototyping, and testing a product concept. The product has not yet been released into the market. Businesses evaluate its viability, do market research, and iterate the product idea depending on user input. Development can be time-consuming and costly, but it is necessary to ensure that the product fits market demands and is technically viable. This period generates little money and typically incurs significant costs.

Key activities: Conceptualization, design, prototyping, market research, feasibility studies.

Challenges: High costs, uncertainty, no revenue generation.

2. Introduction

The introduction stage occurs when the product is released into the market. During this phase, the product is introduced to clients for the first time. Sales typically start slowly as the market becomes acquainted with the product. Companies engage in product marketing and promotions to increase awareness and interest among early adopters. As the company strives to create brand recognition, it may incur large marketing costs and have restricted distribution options.

Key activities: Marketing, advertising, building awareness, and distribution setup.

Challenges: Slow sales, high costs, low market penetration.

Also read: 10 Creative Product Launch Ideas

3. Growth

At the growth stage, businesses see a dramatic uptick in sales and market recognition. As customers become more aware of the product, demand grows. The company may expand its market reach, improve product features, or enhance production capabilities to meet the increasing demand. Competitors may enter the market, but the product typically enjoys a strong brand reputation and customer loyalty. Profit margins also tend to increase as the company achieves economies of scale, reducing costs per unit.

Key activities: Expansion of distribution channels, product enhancements, brand building.

Challenges: Increased competition, maintaining product quality, scaling operations.

4. Maturity

In the maturity stage, the product has reached its maximum market penetration. Sales growth slows as most potential clients have already purchased the goods. The market becomes saturated, and competition increases. Companies frequently use differentiation techniques to maintain market share, such as providing new features, combining items, or altering prices. Profit margins may begin to decline as a result of pricing competition and increased marketing costs. At this point, corporations want to extend the product’s life cycle by making enhancements or exploring new markets.

Key activities: Product differentiation, new marketing campaigns, cost management.

Challenges: Market saturation, intense competition, declining margins.

5. Decline

The decline stage happens when the product’s demand falls, which is frequently caused by technological innovations, shifting consumer preferences, or the introduction of new products. Sales fall, and profit margins narrow. Companies may decide to discontinue the product, cut marketing efforts, or continue selling it at a cheaper price in order to clear inventory. Alternatively, the corporation may decide to reposition or remodel the product to extend its lifespan. Some businesses decide to leave the market entirely if their product no longer satisfies profitability goals.

Key activities: Reduced marketing, cost-cutting, product phase-out.

Challenges: Declining sales, profitability issues, maintaining relevance.

How does a PLM system work?

A PLM system integrates people, processes, and data across the whole product lifecycle. It compiles all product-related information into a single platform, making it readily available to cross-functional teams. PLM systems manage product data, track design changes, and facilitate collaboration across departments such as design, engineering, production, and marketing. These technologies serve to speed product development, decrease errors, increase product quality, and accelerate time-to-market. PLM solutions maintain regulatory compliance and enable efficient decision-making throughout a product’s lifecycle by giving an unified view of the product’s path.

The Evolution of Product Lifecycle Management (PLM)

Product Lifecycle Management (PLM) has come a long way since its early days, transforming from simple document management to an advanced, integrated system that shapes the future of product development. Let’s take a look at it.

1. The Birth of Product Data Management (1980s)

In the early 80s, businesses relied on manual methods to track product designs—spreadsheets, paper blueprints, and the like. Imagine the chaos of misplacing critical files! The introduction of Computer-Aided Design (CAD) and Product Data Management (PDM) software changed the game. Suddenly, product data could be stored digitally, giving engineers more control and reducing errors. This was the dawn of digital design management, and it was a revolution.

2. Bringing Teams Together (1990s – 2000s)

Fast forward to the 1990s—product teams started realizing that it wasn’t just about engineering anymore. Manufacturing, marketing, and supply chains also had a role to play in product success. The concept of collaboration gained momentum. PLM systems evolved to connect different teams across departments and geographies, breaking down silos. A single platform where everyone could share information and work together—now that was a game-changer!

3. The Cloud Revolution (2010s-Present)

Enter the 2010s: cloud computing made waves, and cloud-based PLM systems quickly became a staple. Teams no longer needed to be in the same building to collaborate; they could access data from anywhere in the world. Suddenly, PLM was as flexible and scalable as the cloud itself. This shift also gave rise to AI-driven insights, where businesses could tap into mountains of data to make smarter, quicker decisions. PLM was no longer just a tool; it was an intelligent assistant helping companies innovate faster than ever before.

4. The Age of Digital Twins & AI (Present and Beyond)

Today, PLM is on the cutting edge of technology. With Digital Twin technology and IoT integration, businesses can now create virtual replicas of their products, simulating every detail in real-time. This means products can be tested, optimized, and even tweaked before they are made! Add to that the power of artificial intelligence and machine learning, and you have a PLM system that not only tracks data but also predicts trends, detects issues, and suggests improvements before they even happen.

Also read: Understanding the New Product Development Process

Five Key Advantages of Product Lifecycle Management (PLM)

1. Improved Collaboration

PLM systems centralize product data, allowing for smooth communication across teams. This ensures that everyone, regardless of location, uses the most up-to-date information. Real-time sharing and collaboration facilitate quick decision-making and problem-solving, increasing overall efficiency while minimizing errors.

2. Streamlined Product Development

PLM simplifies product development by automating workflows and tracking progress. Teams can meet deadlines more effectively, minimize bottlenecks, and maintain clear communication, ultimately accelerating time-to-market while reducing project delays and errors.

3. Enhanced Product Quality

PLM improves product quality by monitoring design and production stages. With centralized data and early detection of issues, businesses can address potential defects before they affect customers, ensuring products meet quality standards and customer expectations consistently.

4. Cost Reduction

By streamlining processes, automating tasks, and preventing errors, PLM reduces production costs. Efficient resource management, including inventory optimization, leads to cost savings in materials, labor, and operations, helping businesses remain profitable and competitive.

5. Regulatory Compliance

PLM ensures compliance with industry regulations by tracking all product data. The system automates documentation and safety procedures, keeping businesses aligned with legal requirements. This reduces the risk of fines and legal challenges while ensuring the safety and reliability of products.

Tackling the Challenges of PLM

1. Data Integration Issues

Integrating data from several sources and systems can be difficult in PLM. To address this, firms should invest in powerful PLM solutions that integrate seamlessly with existing tools and software. Organizations may assure smooth data flow by utilizing standardized data formats and APIs, thereby reducing silos and boosting departmental collaboration.

2. User Adoption and Training

Getting employees to embrace PLM systems can be difficult. Overcome this challenge by providing comprehensive training, highlighting the system’s benefits, and offering ongoing support. Ensuring that the system is user-friendly and tailoring it to specific team needs can also encourage adoption and improve efficiency.

3. Customization and Flexibility

PLM systems frequently require customization to meet specific business requirements. To address this, organizations should select scalable systems that allow for simple configuration and customization without relying heavily on IT professionals. Working with a PLM provider to create personalized solutions ensures that the system matches the particular needs of the organization.

4. Cost of Implementation

The initial cost of implementing PLM software can be significant. To overcome this, organizations should focus on the long-term value PLM offers, such as improved efficiency and reduced errors. Implementing the system in phases, starting with critical departments, can help manage costs while maximizing return on investment over time.

5. Data Security Concerns

With the centralization of product data, ensuring its security is crucial. Businesses can mitigate this risk by implementing strong access controls, encryption, and regular audits. Partnering with a PLM provider that prioritizes data security and complies with industry standards helps safeguard sensitive information and prevent breaches.

Also read: RICE Scoring Model: A Prioritization Framework

Evaluating the Success of PLM

1. Time-to-Market Reduction

A successful PLM system speeds up product development, shortening the period from ideation to market launch. This improvement is measured by the amount of time saved throughout each phase of product development. Faster time-to-market implies more revenue and a competitive edge.

2. Cost Reduction

PLM systems help lower costs by minimizing waste, improving resource utilization, and preventing costly errors. By evaluating cost reductions across the product lifecycle, companies can gauge how effectively PLM is managing resources, enhancing profitability and operational efficiency.

3. Improved Product Quality

Success is evident when product quality improves—measured by fewer defects, reduced customer complaints, and higher customer satisfaction. PLM’s role in ensuring consistent quality throughout the design, production, and post-launch stages contributes significantly to meeting quality standards and customer expectations.

4. Adherence

PLM guarantees that goods fulfill industry requirements, which simplifies compliance. Companies may assess their success by reducing compliance difficulties, speeding up approval processes, and ensuring seamless audits. A PLM system that meets regulatory criteria improves business credibility while lowering legal risks.

5. Enhanced Collaboration

PLM fosters cross-functional collaboration between teams, such as design, engineering, and manufacturing. The effectiveness of collaboration can be evaluated through better communication, fewer errors due to miscommunication, and faster problem-solving, signaling successful teamwork across the product lifecycle.

6. Customer Satisfaction

PLM contributes to meeting customer needs by improving product designs and reducing time-to-market. Success is measured by improved customer feedback, satisfaction ratings, and a reduction in product returns. PLM systems that deliver what customers want result in higher loyalty and repeat business.

7. Rate of Innovation

Measuring the rate of new product ideas and innovations is key to assessing PLM success. A greater innovation rate suggests that the PLM system fosters a creative culture and enables teams to bring new ideas to life more efficiently.

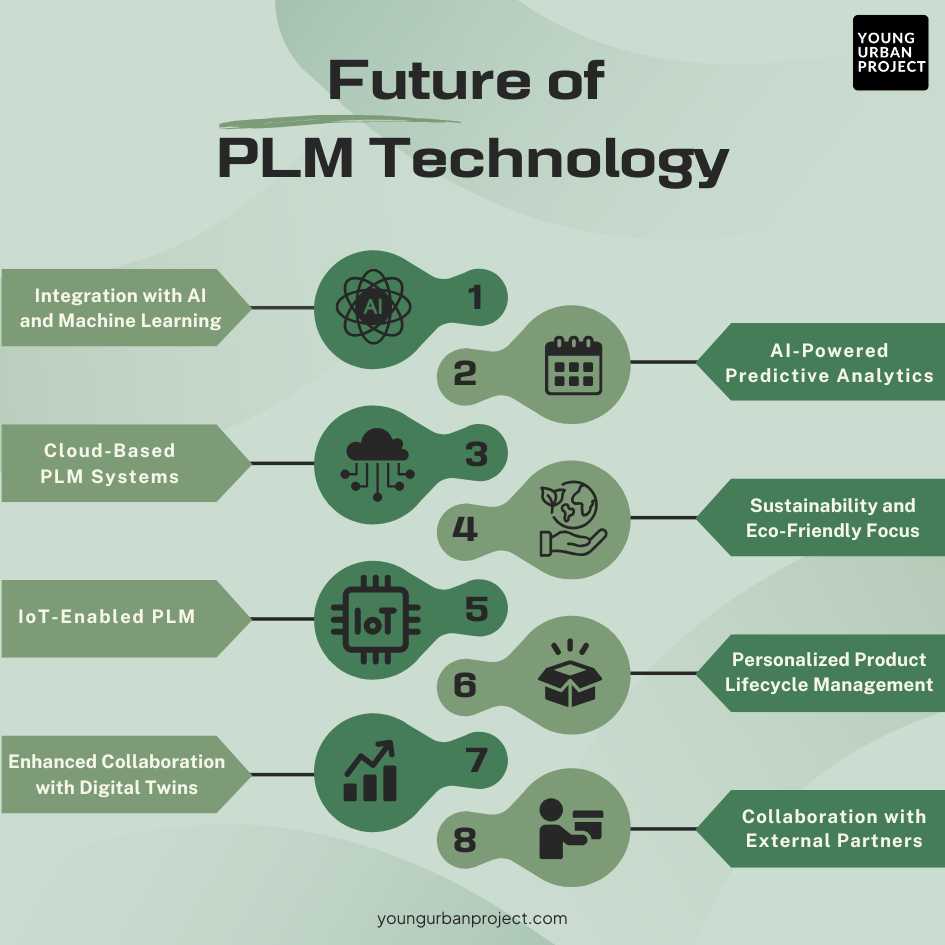

Future of PLM Technology

The future of PLM technology is marked by rapid advancements driven by new technologies and the growing demands of industries. A sneak peek into the future:

1. Integration with AI and Machine Learning

AI and machine learning will play critical roles in automating decision-making, forecasting trends, and increasing product quality. Future PLM systems will use these technologies to evaluate large datasets, anticipate market needs, and optimize designs, increasing product development efficiency.

2. Cloud-Based PLM Systems

Cloud adoption will continue to grow, giving businesses more flexibility, scalability, and remote access to product data. Cloud-based PLM enables teams to interact in real-time, minimize infrastructure expenses, and improve data accessibility across departments and locations.

3. IoT-Enabled PLM

The integration of IoT (Internet of Things) with PLM will allow for real-time monitoring of items throughout their life cycle. From design to post-launch, IoT-enabled PLM will collect data on product performance and condition, which can then be fed back into the design phase to better future iterations.

4. Enhanced Collaboration with Digital Twins

Digital twins—virtual models of physical products—will transform PLM by providing detailed, real-time representations of products throughout their lifecycle. This technology will allow businesses to simulate different scenarios, monitor product performance, and predict issues before they occur, fostering collaboration across teams.

5. AI-Powered Predictive Analytics

Predictive analytics will transform PLM systems, providing insights into market trends, customer wants, and product lifecycle performance. PLM systems will assist firms in making better decisions, allocating resources more effectively, and optimizing product design by analyzing historical data using AI.

Also read: Generative AI vs Predictive AI

6. Sustainability and Eco-Friendly Focus

As environmental concerns grow, the future of PLM will focus on sustainability. PLM systems will integrate eco-friendly design principles, allowing businesses to track environmental impact throughout the product lifecycle. This will help companies meet sustainability goals while maintaining profitability.

7. Personalized Product Lifecycle Management

PLM will become more personalized as AI and data analytics technologies evolve. Systems will adapt to specific product kinds, industries, and business models, enabling customized solutions that improve the user experience and streamline product lifecycle management across several industries.

8. Collaboration with External Partners

Future PLM systems will improve collaboration not only within enterprises, but also with outside partners, suppliers, and customers. Businesses can develop products faster and more efficiently by enhancing communication and data exchange, resulting in better partnerships and a shorter time-to-market.

Conclusion

In conclusion, Product Lifecycle Management (PLM) plays a pivotal role in modern businesses by effectively managing each stage of a product’s journey, from development to decline. By leveraging PLM software, companies can streamline processes, improve collaboration, and enhance decision-making throughout the entire lifecycle. From product data management and regulatory compliance to problem solving and creativity, PLM solutions enable firms to build high-quality, successful products. As technology advances, the future of PLM promises intriguing possibilities such as AI, IoT, and blockchain integration, all targeted at improving product lifecycle management even more. Understanding the many stages, features, and use cases of PLM is critical for firms seeking long-term success and viability in a competitive market.

FAQs

1. What does the product lifecycle refer to?

The product lifecycle refers to the series of stages a product goes through from its initial concept and development to its eventual decline and retirement. These stages typically include product development, introduction, growth, maturity, and decline. Understanding this lifecycle helps businesses manage and optimize each phase to maximize a product’s value and success in the market.

2. What is a PLM system?

A PLM (Product Lifecycle Management) system is a software solution that helps businesses manage a product’s entire lifecycle, from ideation to retirement. It centralizes product data, ensures efficient collaboration, tracks changes, and improves decision-making across teams. PLM systems help streamline processes, reduce time-to-market, enhance product quality, and ensure regulatory compliance.

3. How does PLM differ from PDM (Product Data Management)?

While both PLM and PDM focus on managing product data, PLM goes beyond data management to encompass the complete product lifecycle. PDM generally handles product design data and documents during the design phase, whereas PLM incorporates design, production, and even product retirement, with an emphasis on whole lifecycle management, such as collaboration, compliance, and business strategy.

4. How do manufacturers adapt to industry disruptions?

Manufacturers adapt to disruptions by embracing new technologies, flexible supply chain strategies, and innovation-focused PLM systems. PLM allows manufacturers to quickly adjust designs, improve collaboration, and optimize production processes. By leveraging data and analytics, companies can make informed decisions to navigate disruptions, stay competitive, and meet shifting market demands effectively.

5. What are the common challenges of implementing PLM?

Implementing PLM comes with challenges such as resistance to change from employees, data migration complexities, integration with existing systems, and high upfront costs. Additionally, ensuring user adoption, maintaining data accuracy, and aligning PLM processes with business goals can pose significant hurdles. Overcoming these challenges requires strategic planning, training, and long-term commitment.

6. How do you evaluate the success of PLM initiatives?

The success of PLM initiatives can be measured through metrics like reduced time-to-market, cost savings, improved product quality, and enhanced collaboration. Other indicators include increased innovation, better regulatory compliance, and a reduction in product defects or failures. A successful PLM system leads to improved efficiency, customer satisfaction, and more profitable product lifecycles.